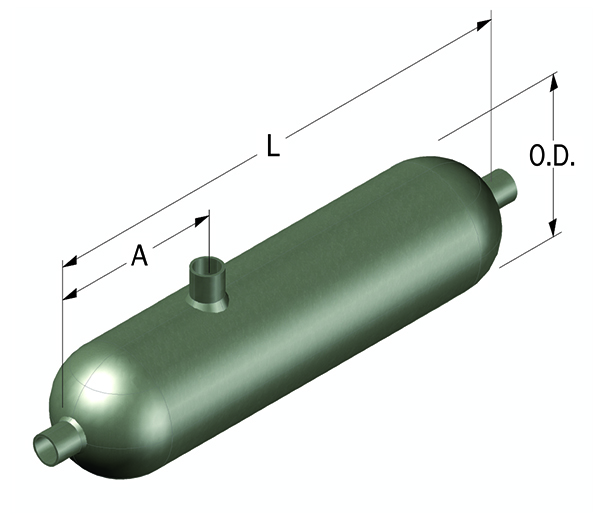

Condensate chambers, also known as condensate seal pots or steam condensate drip pots, are welded pressure vessels that allow instruments and valves to be attached in line with routed tubing to allow for line sampling, elimination of fluid, and other processes. Condensate seal pots are used to protect sensitive metering systems and devices by trapping and holding condensate and foreign material that may accumulate in gaseous service lines. TechLine Mfg. condensate chambers are also used as a liquid barrier between the mainline and the secondary instruments to prevent steam, vapors, and corrosive/viscous process fluids from reaching those instruments. TechLine Mfg. stocks a number of prefabbed standard condensate chamber sizes, and we also provide custom seal pots based on customer requirements. Contact us to let us know what you need.

Manufacturing Process of Condensate Chambers

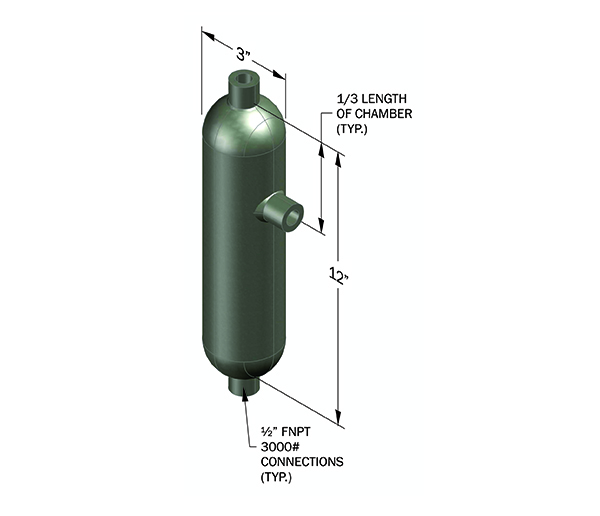

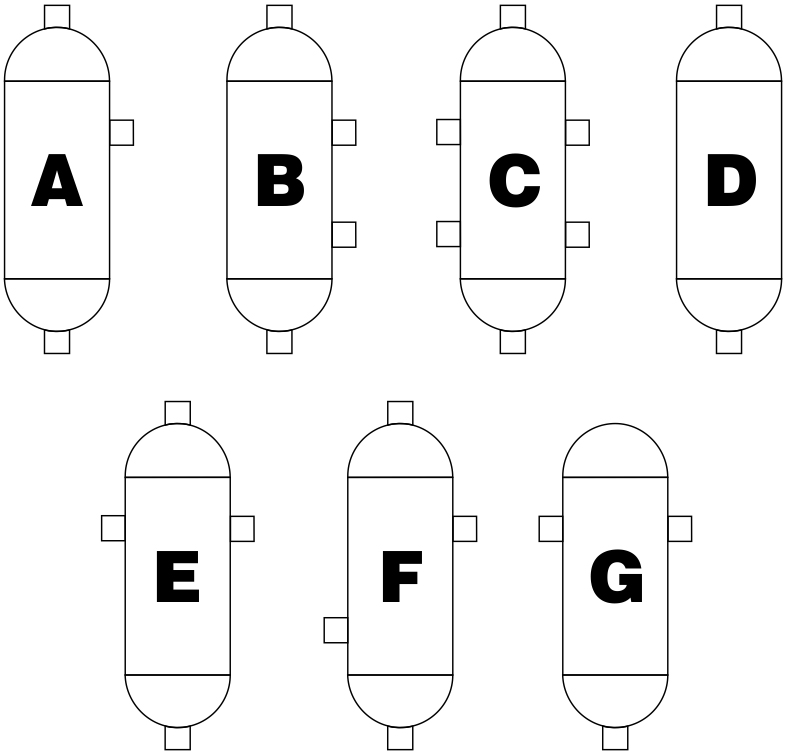

Steam Chambers consist of a piece of seamless pipe with butt weld caps welded on each end. Connections are then welded in the desired position specified by the end user. TechLine Mfg. offers stock availability for “A” configuration 2x12 and 3x12 sizes in carbon steel and 316ss.

Steam Condensate Drip Chamber Industries

Since TechLine Mfg. condensate chambers are used to protect sensitive metering systems and devices, they are used in a variety of industries to trap and hold foreign materials that may accumulate in gaseous service lines. TechLine Mfg. manufactures condensate seal pots for the following industries:

- Chemical plants

- Oil & Gas plants

- Power Generation plants

- Steel plants

Condensate Chamber Materials

TechLine Mfg. manufactures condensate chambers in carbon steel and stainless steel. If higher pressures are being used, P-91, P-21, P-11 are common materials we work with to withstand higher temperatures and pressures. We recommend using stainless steel for steam condensate drip pots because of its long-lasting characteristics. Carbon steel is the most cost-effective material used for condensate chambers, and hot dipped galvanizing is an option to prolong the life of a carbon steel seal pot.

Aluminum and copper cannot be used for chambers due to their softer natures.

Pressure Testing for Condensate Chambers

Pressure testing is part of the ASME standards that TechLine Mfg. follows when building condensate seal pots. Each chamber is tested to a pressure determined by our production manager that is based on the material type used and the thickness. This ensures that there are no flaws in the welds or material while under pressure.

X Ray & Dye Pen Testing for Steam Condensate Chambers

When requested, x-ray and dye penetrate testing can be performed to record film that shows that there are no non-unions and pinholes that would leak or weaken the state of the material while under high pressure and temperature. If your project requires these tests, please request a quote and we can provide pricing according to your specific need.

ASME Standards

Pressure Vessels are manufactured following Welding Procedures under provisions of ASME Section IX and hydrotested under provisions of ASME Section VIII Div I: UG-99

Condensate Chamber Quote Request

TechLine's Condensate Chambers are manufactured dependent on your specifications.

In order to provide a detailed quote, please fill out our custom order form and include your requirements.