Industrial Instrument Stands

Instrument stands, or instrument supports are used to mount various measurement instruments or control devices (i.e., analyzer, emergency stop buttons or switches) in an industrial setting. TechLine Mfg. manufactures instrument stands using schedule 40 welded pipe, 3/8” or ½” thick base plates with round or slotted holes, and gussets if requested. We are able to provide standard sized pre-fabbed instrument stands that can be shipped the next day, which are typically less expensive than a custom stand. Our standard stock sizes can be specified in the drawings, and don’t require additional time for drawing, further saving money. TechLine Mfg. also specializes in custom fabrication, and will be happy to build to your drawing or help you design to your requirements.

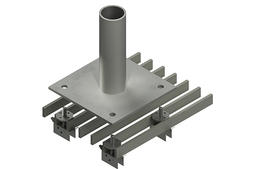

Standard TechLine Mfg. instrument stands are fabricated from 2" Schedule 40 Pipe, along with 8" X 8" X 3/8" base plates and utilize a flat cap design.

- Standard stands are Hot Dipped Galvanized Carbon Steel meeting ASTM A123/89 requirements.

- We also offer Aluminum, 304SS, 316 SS, Powder Coated and Painted.

- Optional Coatings are available. Click here to fill out a request form.

- Hot dipped galvanized stands come standard with weep holes and an open base to allow for drainage.

- Custom stands are available. Call or fill out our contact form to let us know what you need.

- Bag & Tag/Kits available

Instrument Stand Applications & Industries

Industrial instrument stands are commonly used for level gauge, flow meter, start-stop button mounting and any other secondary instrumentation mounting or support that may be needed. TechLine Mfg. provides instrument stands to the following industries:

- Chemical

- Power generation

- Automation

- Manufacturing

- Oil and Gas

- And many others

Instrument Stand Materials

TechLine Mfg. offers pre-fab and custom instrument stands in Aluminum, 304 and 316 stainless steel, and hot dipped galvanized carbon steel. Galvanized steel is most readily available and cost-effective, while the other materials have better appearances and weather resistance.

- Hot-dipped Galvanized per ASTM A-123

- Powder Coat

- Aluminum

- 304 SS

- 316 SS

- Painted

| Material | Benefits |

| Aluminum |

Lighter/cost effective option |

| Galvanized Steel |

More rigid/ heavier option |

| Stainless Steel |

Highest tolerance from rust/corrosion |

Custom Fabrication:

With our onsite fabrication facility, TechLine Mfg. can handle any of your custom requirements. Contact us for more information and to let us know what you need.

Send us your drawing and we will build it or take a look at our brochure below: