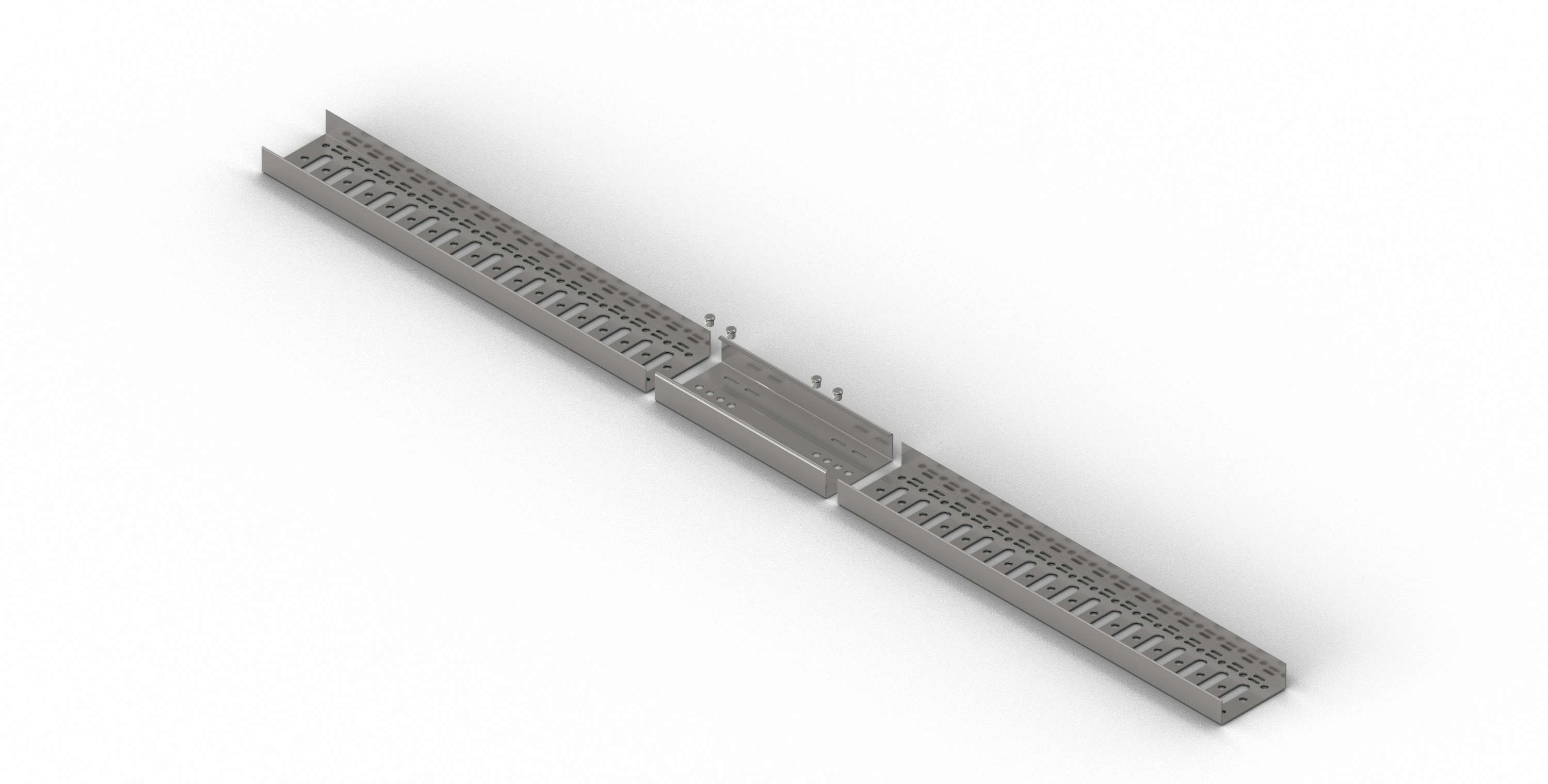

Save on total installed costs with Snap Track Ventilated Channel System.

Our signature cable tray system, Snap Track channel tray, which requires fewer supports and less labor to install, saves on total installed costs.

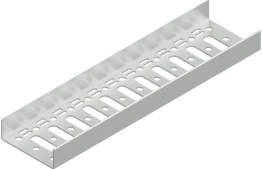

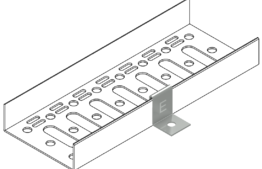

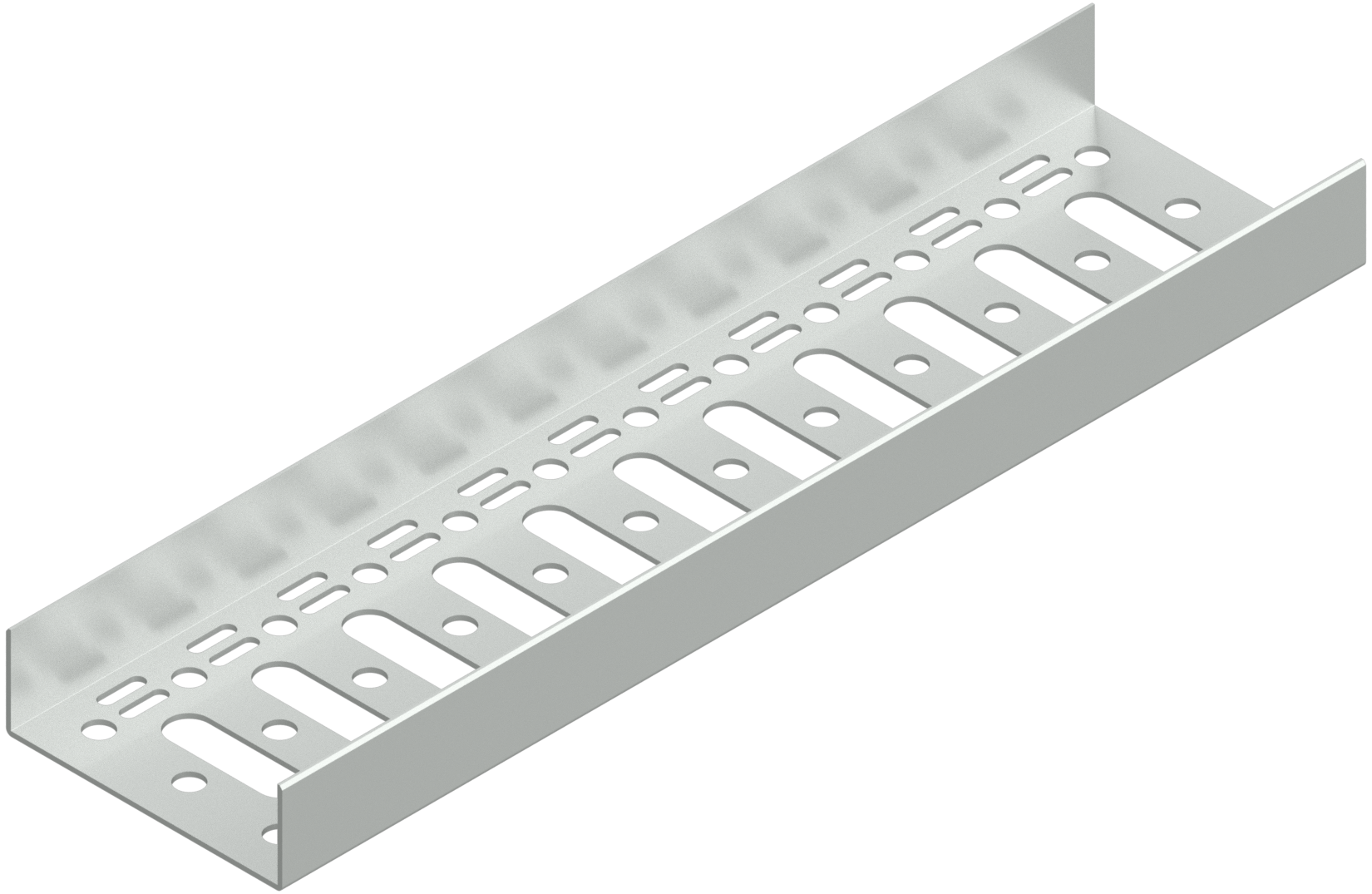

Snap Track, TechLine Mfg.’s innovative ventilated channel type industrial cable tray, is a UL Classified product with patented push-pin assembly, and is an excellent choice for supporting electrical and analyzer cabling, as well as tubing, in industrial plants, commercial buildings, food and beverage facilities, and other applications. As a less-expensive alternative to conduit, and a stronger alternative than wire basket, and superior to generic tray, the Snap Track cable tray system saves on labor and reduces total installed costs. Snap Track Channel is available in 2”, 4” and 6” widths.

Industrial Cable Tray System Features & Benefits:

Industrial Cable Tray System Features & Benefits:

- Quick, easy installation, saves labor

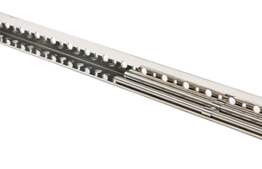

- Unique patented push-pin assembly requires less time to install without using tools

- Longer span distances require fewer supports, increasing cost savings

- Large selection of fittings reduces field labor

- Allows flexibility for future cable runs and routing changes

- UL Classified marine grade 6063-T6 aluminum is strong, lightweight, and corrosion resistant

- Hole pattern allows for easy cable drop outs

- Large inventories ready to ship

- Product Design Assessment (PDA) completed by ABS

Schedule a no-obligation Product Seminar to learn more about how SnapTrack can benefit your next project.

Industries & Applications

- Petroleum Refineries

- Chemical Processing

- Offshore and Marine

- Biofuel Facilities

- LNG Export Facilities

- Food and Beverage

- Power Generation

- Commercial Construction

- Renewable Energy

- Data management

- Solar Installations

- Carbon Capture

Snap Track Cable Tray Background

Snap Track was developed as a limited-width cable tray system to replace wire basket tray, conduit, and generic tray. It is stronger, provides better cable protection, and reduces installation costs through its push-pin assembly and reduced support requirements, making it a superior industrial cable tray.

Snap Track is

- An innovative channel tray system providing cable protection in a wide range of industries and applications

- A unique limited-width ventilated bottom channel tray, to be used as an alternative to conduit, wire basket, or generic tray. Snap Track transitions control, power, data, and instrument cables from ladder try to point of use, i.e., instruments and motor control stations.

Commonly accepted benefits of running channel tray systems in lieu of conduit include

- Reduced total installed costs

- Cable accessibility

- Ease of future modifications

- Labor and material savings

UL Classification for Industrial Cable Trays

The Snap Track system has been tested and is classified by Underwriters Laboratories for both UL and CUL (File Number E249472). Electrical continuity is achieved through our unique, extruded, inward C formation and snug-fitting splice. A bonding jumper is required ONLY for adjustable fittings, expansion splice plates, and beginning/end of tray runs, as to provide continuity. All other fittings used with push pins typically require no bonding jumpers. Click here for more information on grounding and bonding.

ABS Product Design Assessment

The American Bureau of Shipping has completed a design assessment of Snap Track, approving it for use in marine/offshore environments.

Schedule a no-obligation Product Seminar to learn more about how Snap Track can benefit your next project.

Scroll to the bottom to view All Snap Track Cable Tray Cut Sheets

Click here to view TechLine Mfg.’s Full Product Catalog, including Snap Track.

Additional Resources:

Snap Track vs. Conduit Cost Comparison

To answer common questions regarding the advantages of Snap Track vs. Conduit, TechLine Mfg. recently published a technical paper on a comparison of total installed costs of Snap Track vs. Conduit.